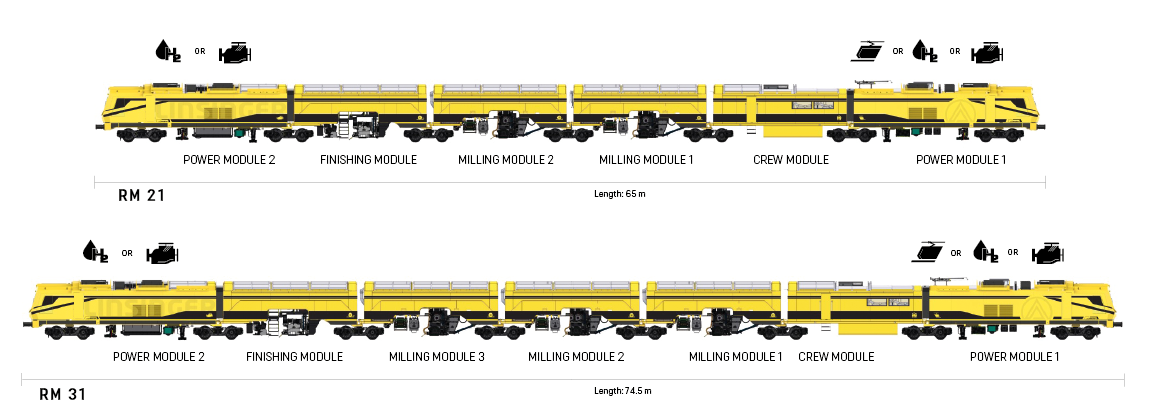

RAILMASTER ®

high performance rail milling technology

with two independent drives

#trusttheinventor

the machine is available with hydrogen, a pantograph oder diesel drive

That´s why Railmaster®

| TECHNICAL SPECIFICATIONS | |

| Type of drive of the processing units (milling/finishing) | electric |

| Traction drive | electric |

| Max. axle load | 20 t |

| Removal per pass | 0.1 - 6 mm |

| Roughness after processing | < 5 µm |

| Processing speed (feed) | Up to 2000 m/h |

| Speed towed | max. 120 km/h |

| Speed self-propelled pantograph | max. 120 km/h |

| Speed self-propelled other drives | max. 100 km/h |

Any questions?

Contact us!

POWERED BY