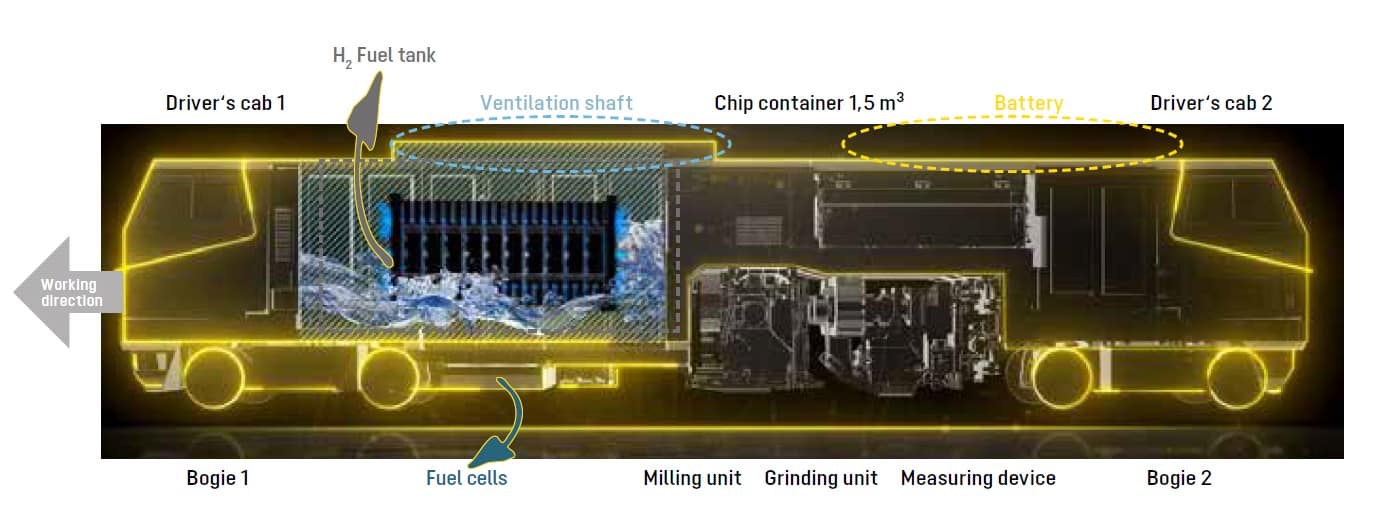

RAIL MILLING TRAIN MG11 HYDROGEN

WORLD‘S FIRST RAIL RE-PROFILING WITHOUT EMISSIONS

#trusttheinventor

ZERO EMISSION

Sie sehen gerade einen Platzhalterinhalt von Standard. Um auf den eigentlichen Inhalt zuzugreifen, klicken Sie auf den Button unten. Bitte beachten Sie, dass dabei Daten an Drittanbieter weitergegeben werden.

Weitere InformationenHIGHLIGHTS

Any questions?

Contact us!

APPLICATIONS

HOW SAFE ARE LINSINGER HYDROGEN VEHICLES?

Hydrogen is a very safe fuel and less flammable in the earth’s atmosphere than conventional fuels (gasoline, diesel). The gas is stored in extremely stable tanks. Even in the very rare case of a gas leak, gas cannot accumulate. Hydrogen is fourteen times lighter than air and therefore escapes into the atmosphere quickly and harmlessly.

The handling of hydrogen is subject to established safety guidelines. Defined tests are prescribed for machines and machine parts (e.g. pressure, leakage, burst and fire safety tests). Linsinger hydrogen rail milling trains meet these European safety standards.

How safe are Linsinger Hydrogen Trains?

An accompanying development test is conducted by TÜV Süd Rail GmbH who also carries the risk analysis in cooperation with Linsinger out.

The hydrogen storage tanks (= composite material tanks) are installed inside of the machine and therefore optimally positioned in terms of safety. These composite material containers consist of a plastic core which is wrapped with carbon fibres. The design allows hydrogen to be stored under high operational pressure and for years of use.