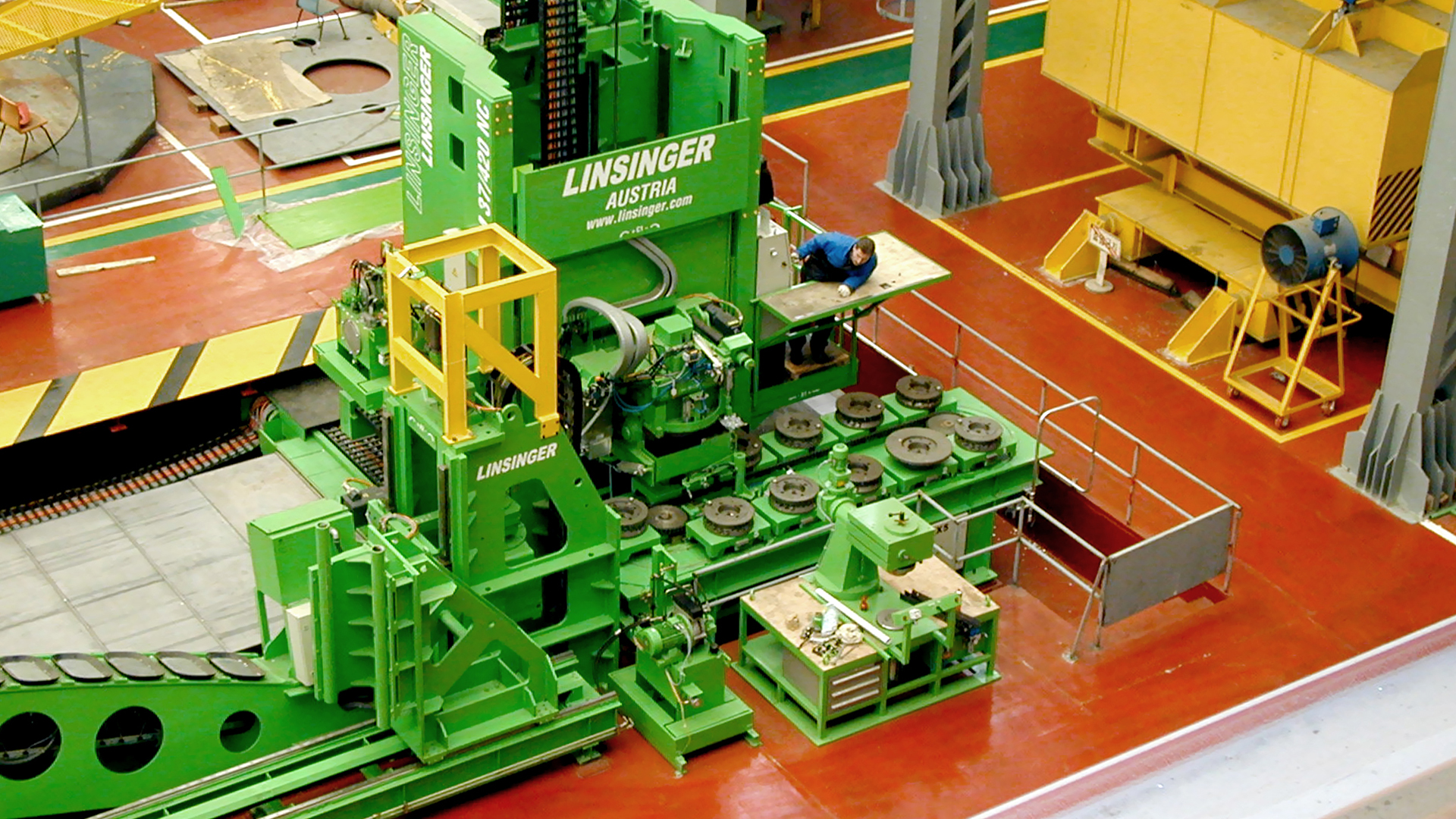

special milling equipment for shipbuilding

ANY QUESTIONS?

PLEASE CONTACT US FOR DETAILS

HIGHLIGHTS

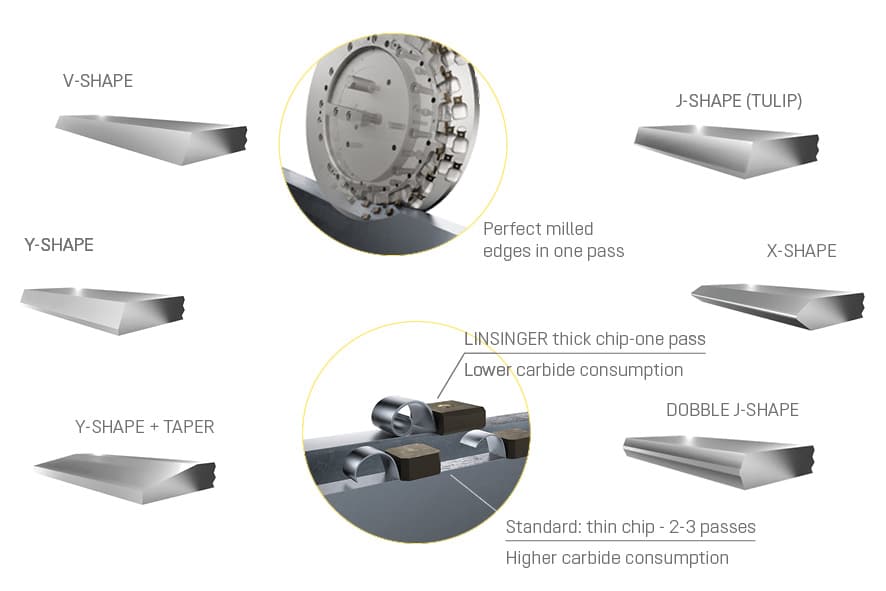

WELDING EDGE PREPARATION FOR STEEL BEAMS

STEEL BEAM PROFILES

HIGHLIGHTS

ANY QUESTIONS?

PLEASE CONTACT US FOR DETAILS

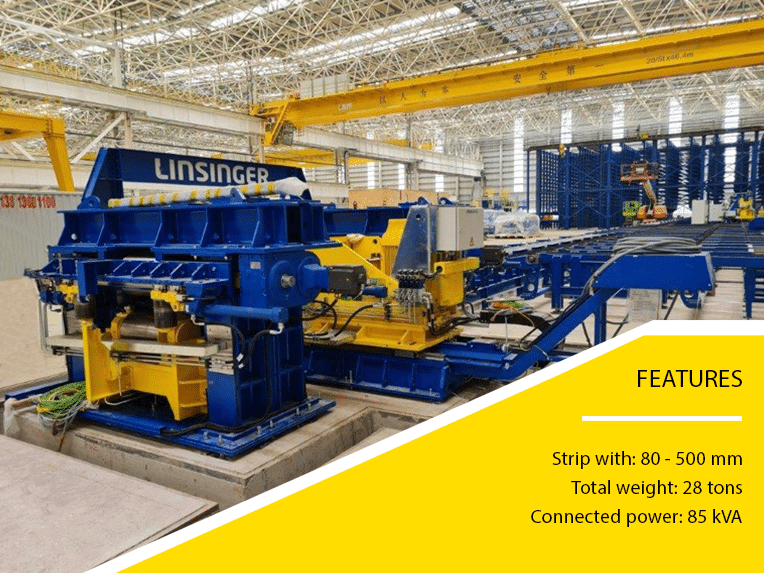

HIGHLIGHTS

ANY QUESTIONS?

PLEASE CONTACT US FOR DETAILS

U-BOOT LUKENFRÄSANLAGEN

ZUR BEARBEITUNG VON U-BOOT-LUKEN

FEATURES

configuration