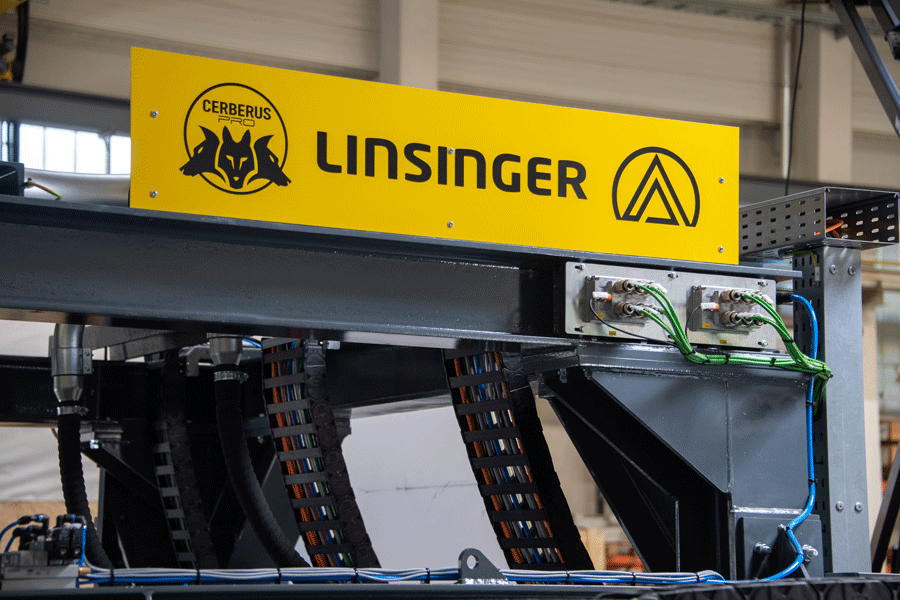

CERBERUS

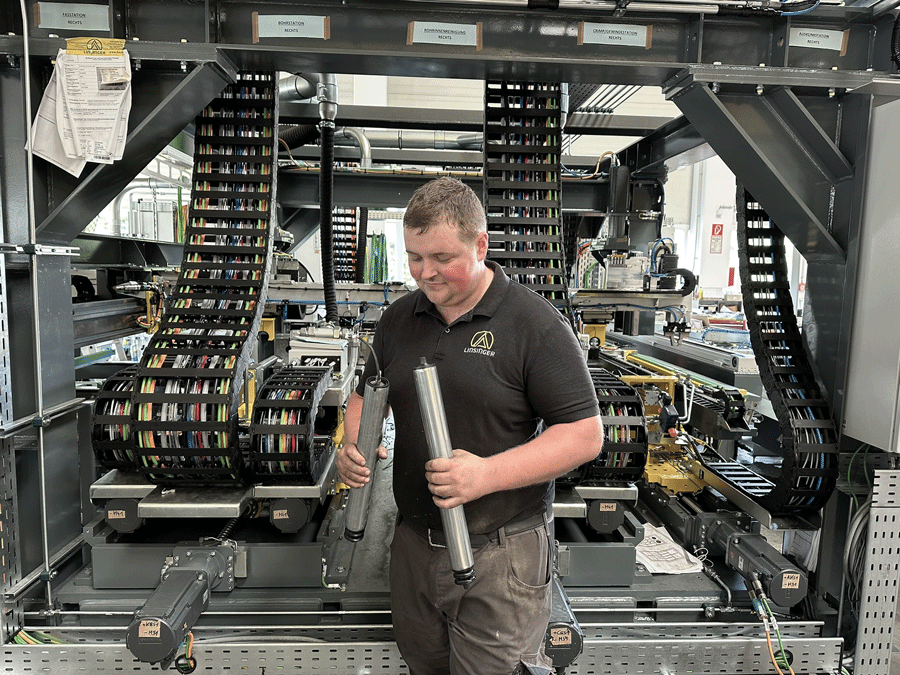

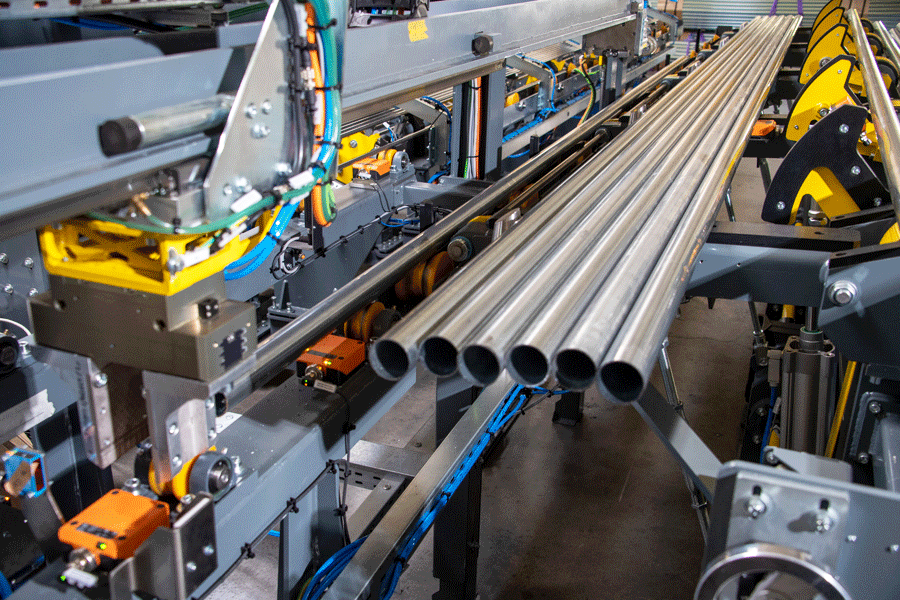

automatic production line of individual roller manufacturing

A PERFECT MACHINE CONCEPT

PRODUCTIVITY – High output with low personnel costs

QUALITY – Integration of quality control through condition monitoring

ECONOMIC EFFICIENCY – From pre-material to finished roll – Just in time

APPLICATION

FEATURES

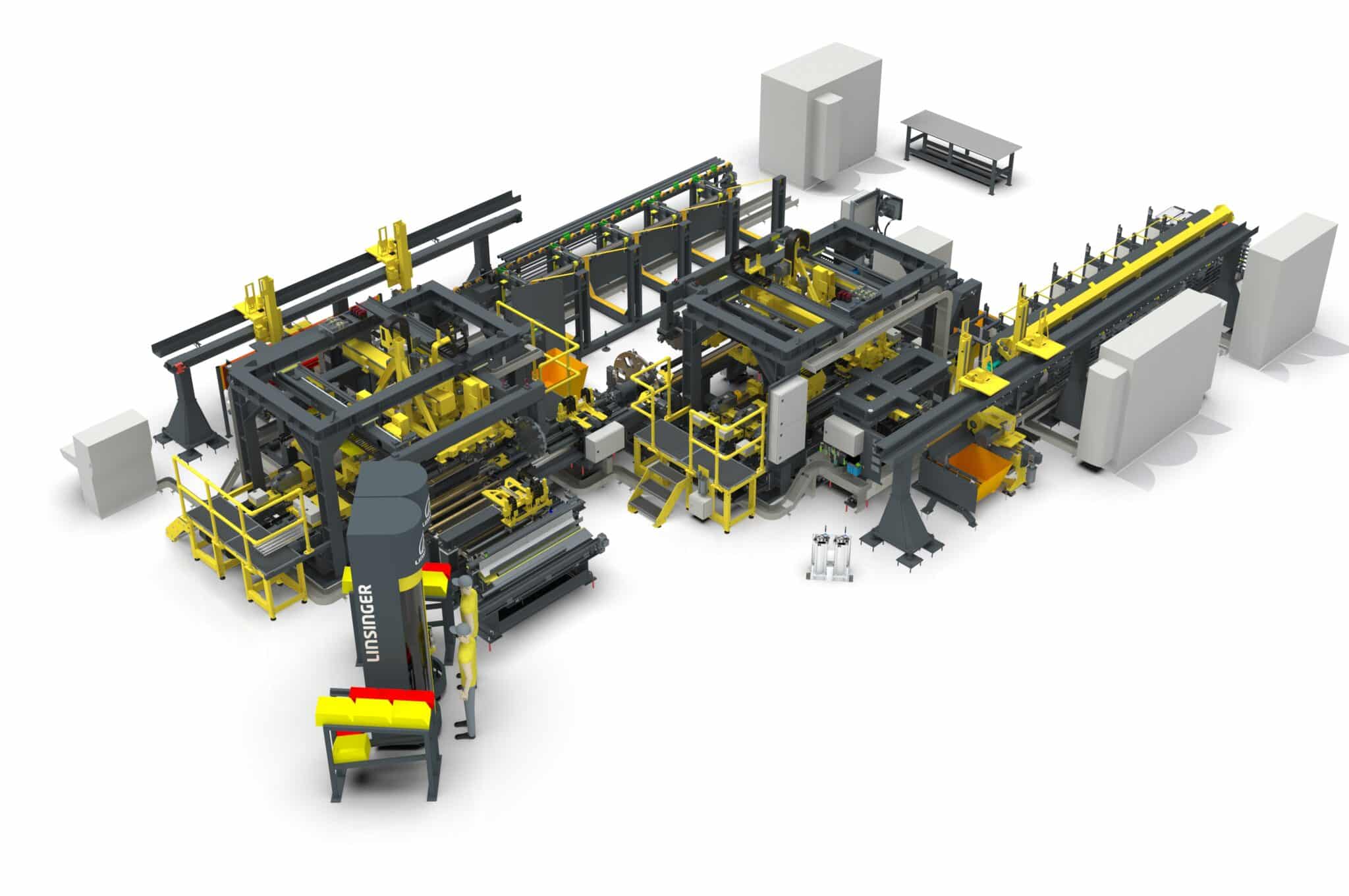

Standard configuration of transport roller plants

| CERBERUS MAX | CERBERUS PRO | CERBERUS FLEX | |

|---|---|---|---|

| Tube (mm) | 30-60 | 30-60 | 30-60 (105) |

| Axle | 8-14/HEX 8-14 | 8-14/HEX 8-14 | 8-14/HEX 8-14 |

| Thread | M6-M10 | M6-M10 | M6-M10 |

| Roller length | 100 -1500 | 100 -1500 | 100 -1500 |

| Roller cycle time (Reference)* | ≤ 5 sec. | 7-10 sec. | 7-20 sec. |

| Material | Steel/Stainless steel | Steel/Stainless steel | Steel/Stainless steel |

| Production method | yes, order related | conditionally batch optimized | yes, order related |

| Simultaneous production of tubes and shafts | yes | yes | no |

| Merging of tubes and shafts | yes | yes | no |

| Assembly Station | optional | optional | optional |

Combined tube and axle system with an integrated assembly station

The CERBERUS MAX produces transport rollers in batch size 1 with a cycle time of just 5 seconds 100% automatic quality inspection of all rollers.

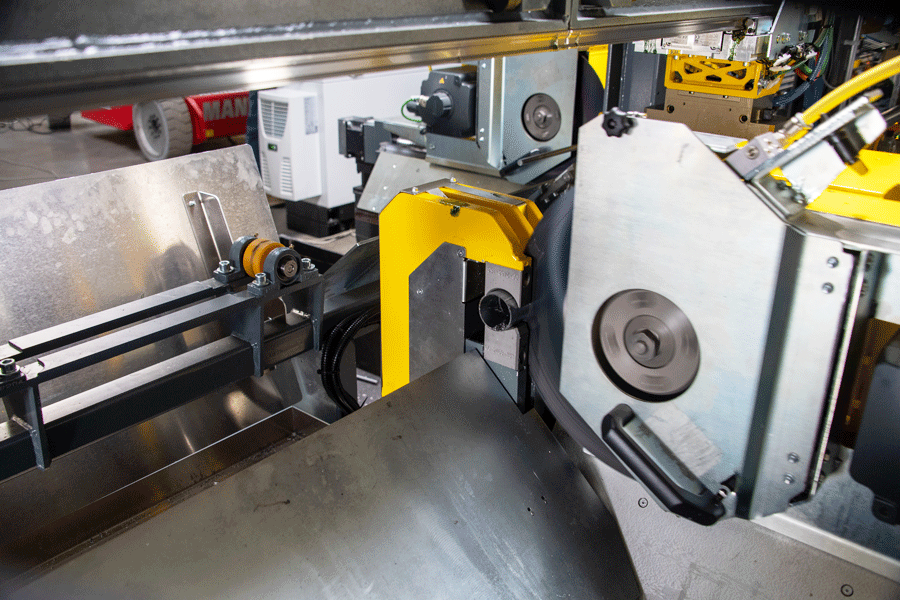

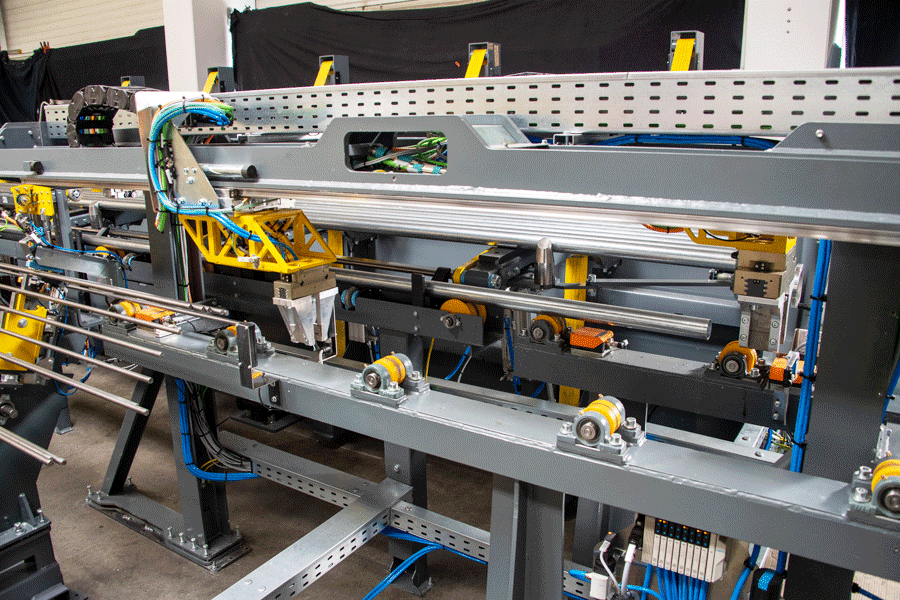

Combined Tube and Axle System with Optional Semi-Automatic Assembly Station

Compact unit with high performance for batch-based manufacturing.

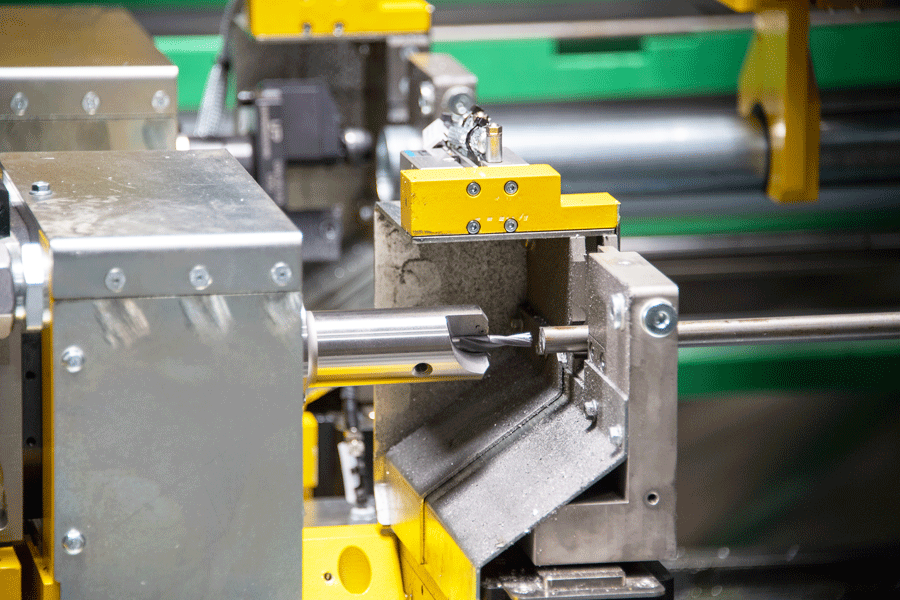

AUTOMATIC TUBE AND AXLE PROCESSING SYSTEM

Sequential production of tubes and axles for individual products