Special Sawing Machines

FEATURES

ANY QUESTIONS?

PLEASE CONTACT US FOR DETAILS!

HIGHLIGHTS

ANY QUESTIONS?

PLEASE CONTACT US FOR DETAILS!

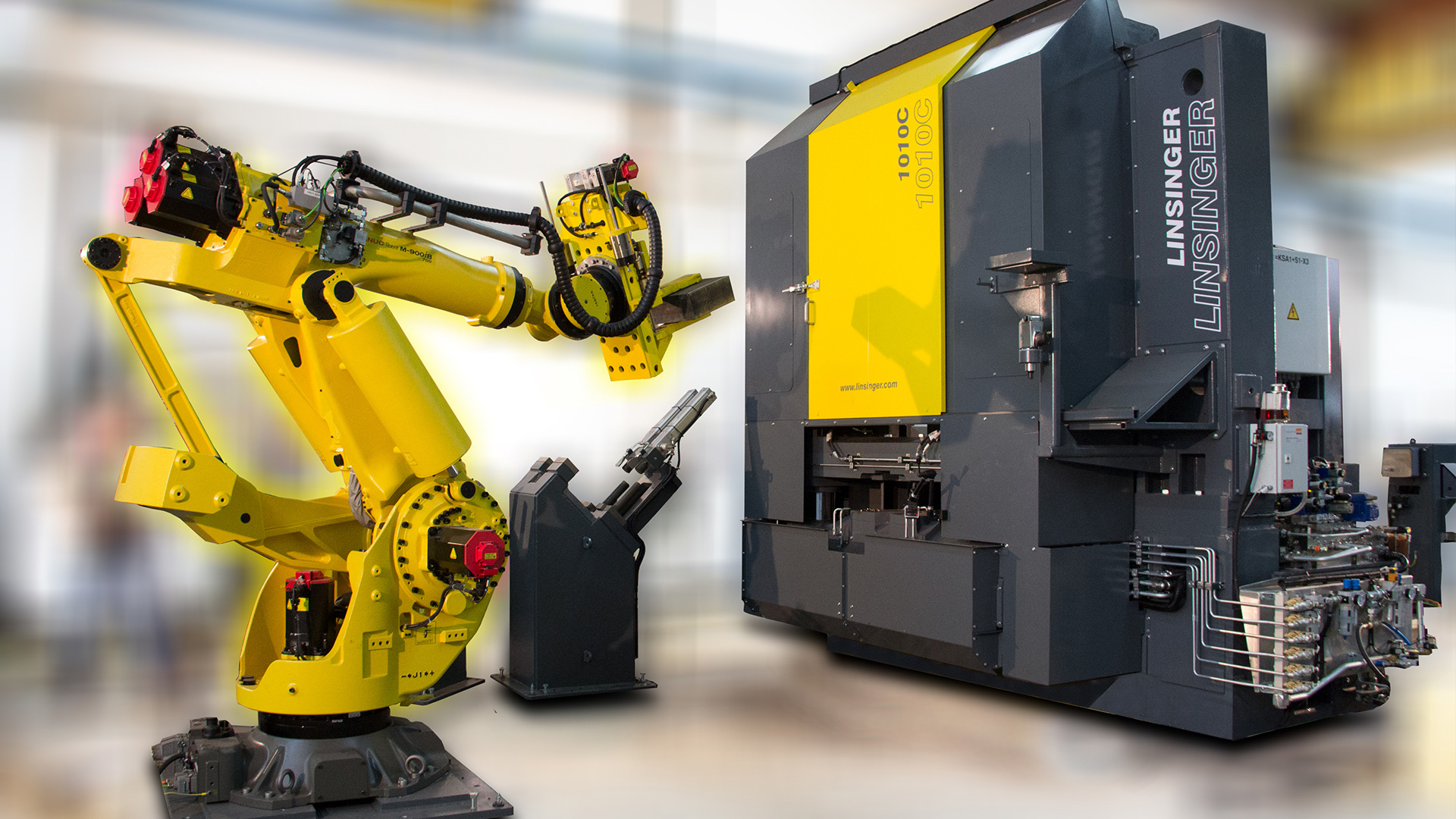

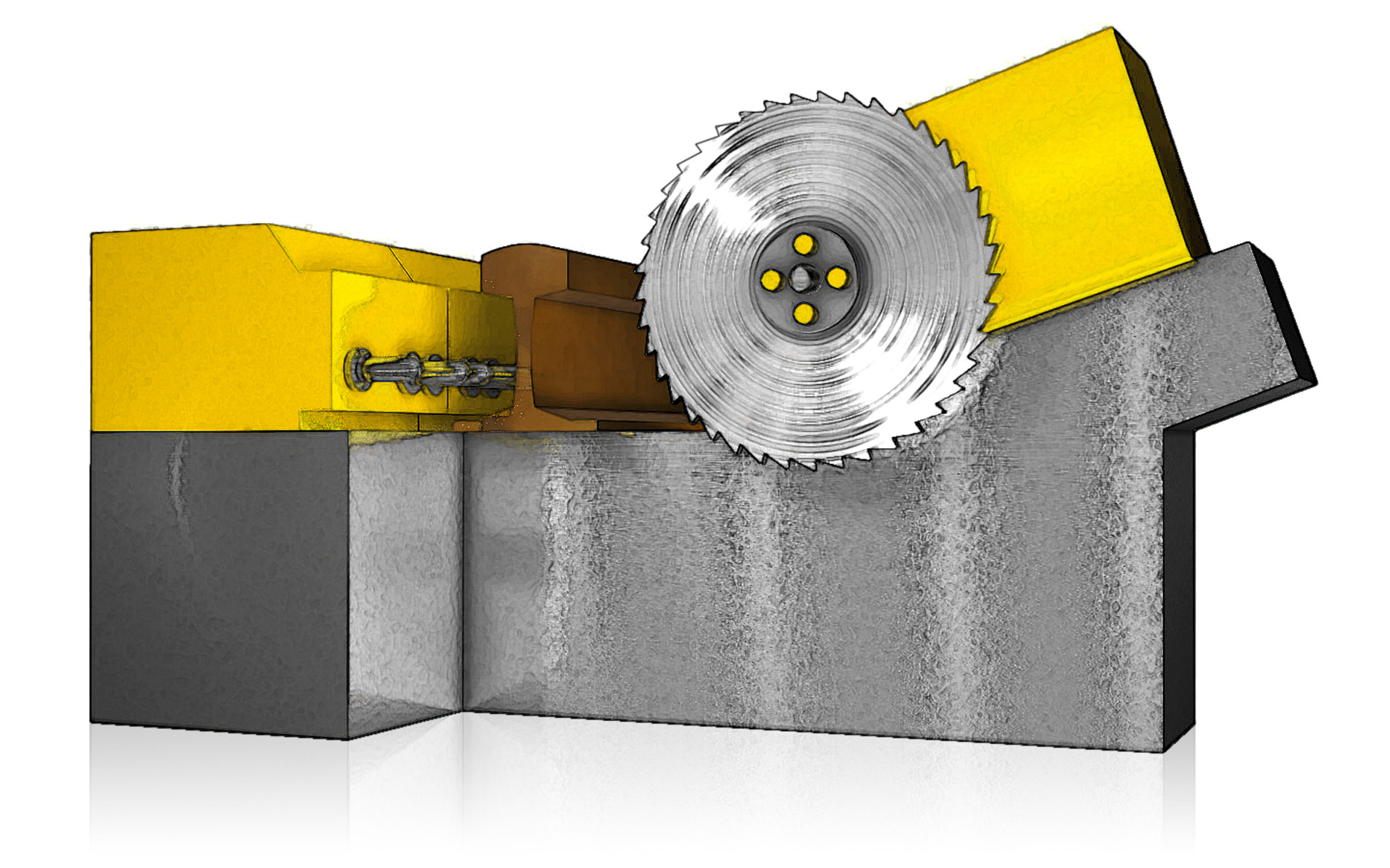

RAIL SAWING AND DRILLING MACHINE LSB

CYCLE TIME 30 SECONDS

ONE SAW CUT AND SIX DRILLED HOLES

Technical Data

| TYPE | QTY DRILLS | RAIL HxB MAX |

| KSA 500 S | 0 | 190 x 160 mm |

| LSB 800 | 0 | 200 x 220 mm |

| LSB 800/S1 | 1 | 200 x 220 mm |

| LSB 800/S2S | 1* | 200 x 220 mm |

| LSB 800/S3 | 3 | 200 x 220 mm |

| LSB 800/S6 | 6 | 200 x 220 mm |