Plate Edge Milling Machine PFM

FIELDS OF APPLICATION

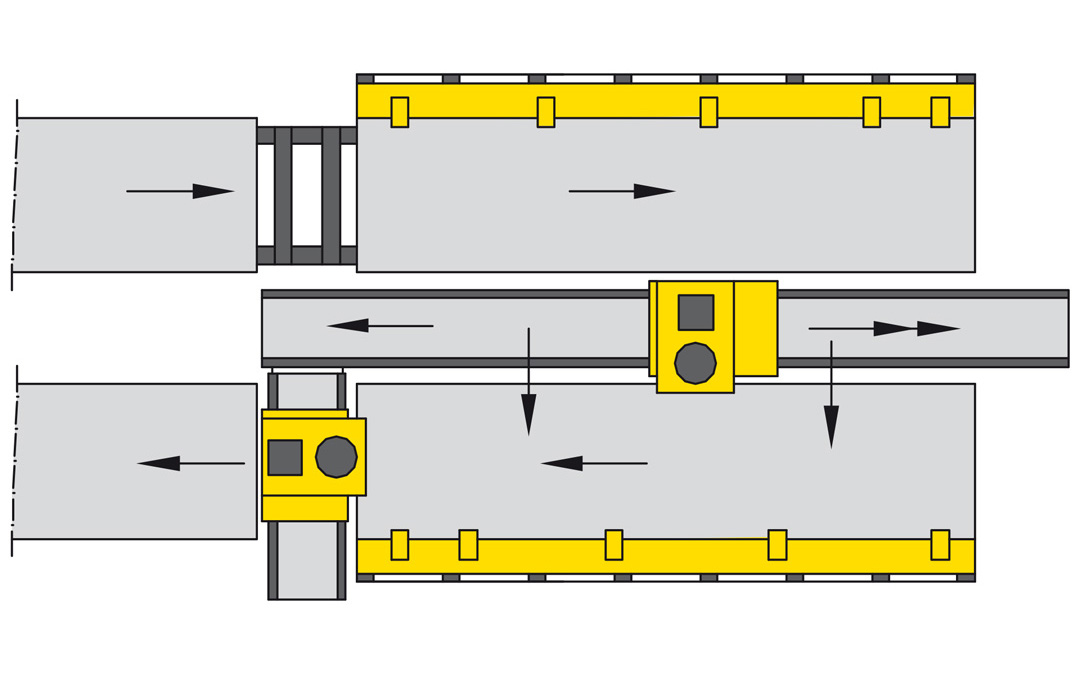

FOR LARGE PIPES, SIMULTANEOUS PREPARATION OF WELDED EDGES ON BOTH LONGITUDINAL SIDES

INCREASED OUTPUT

| THROUGH PRECISE WELD PREPARATION |

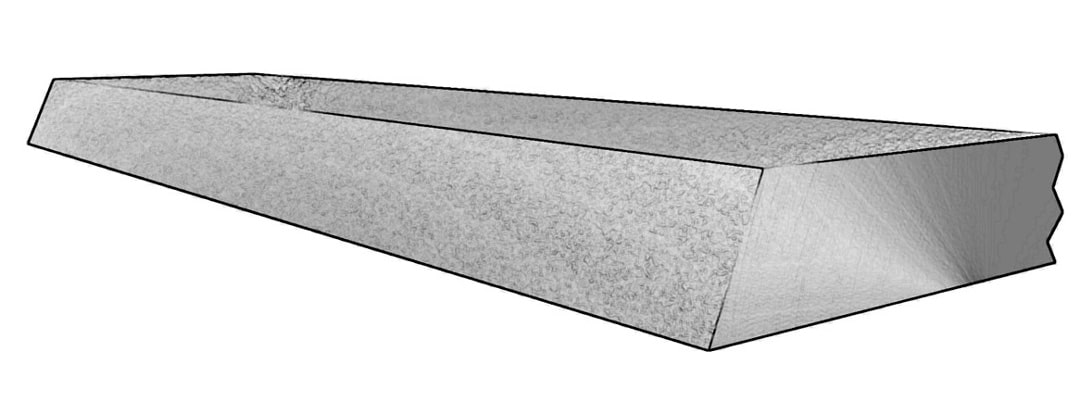

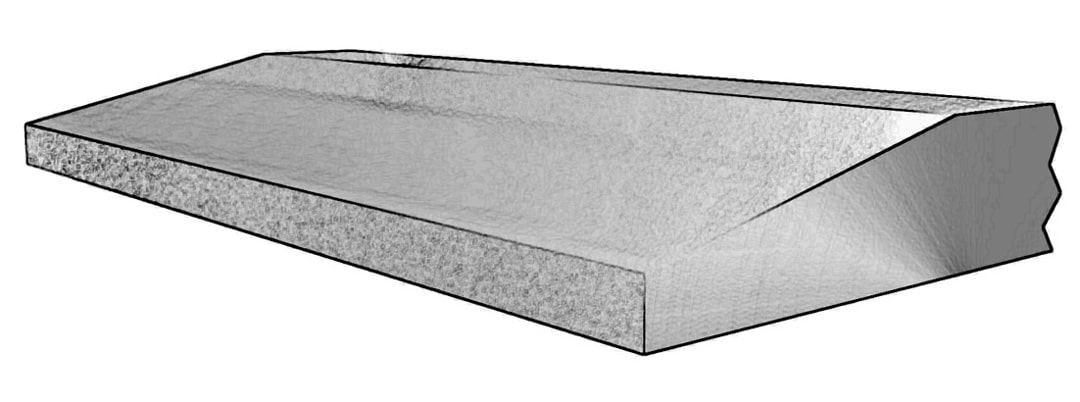

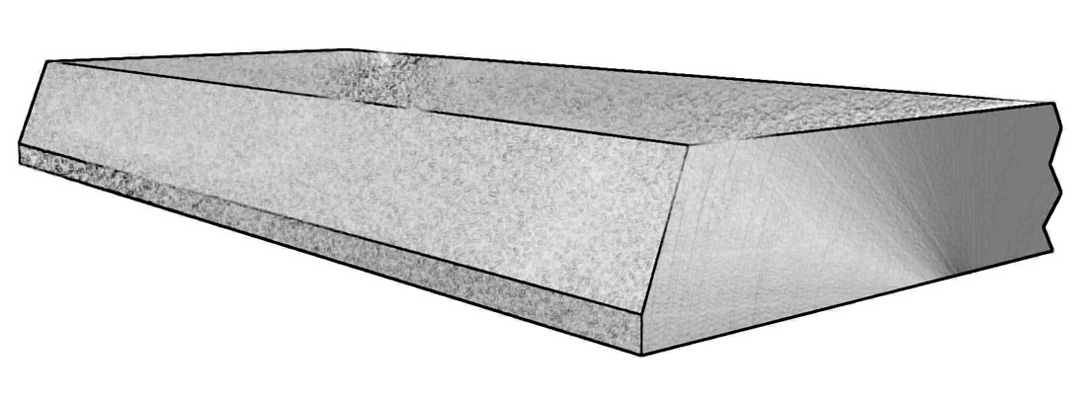

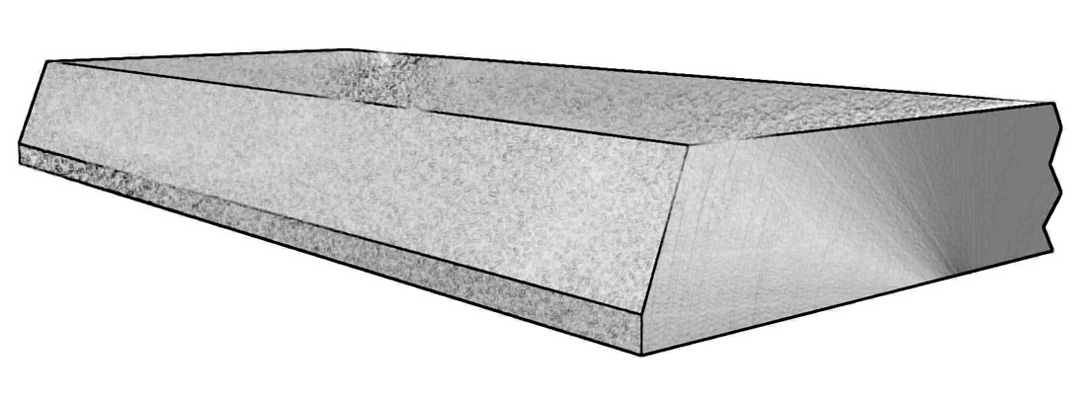

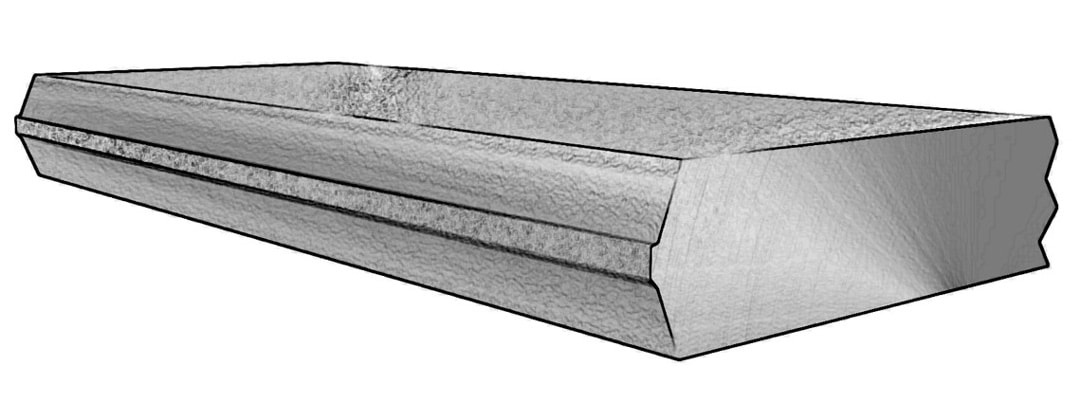

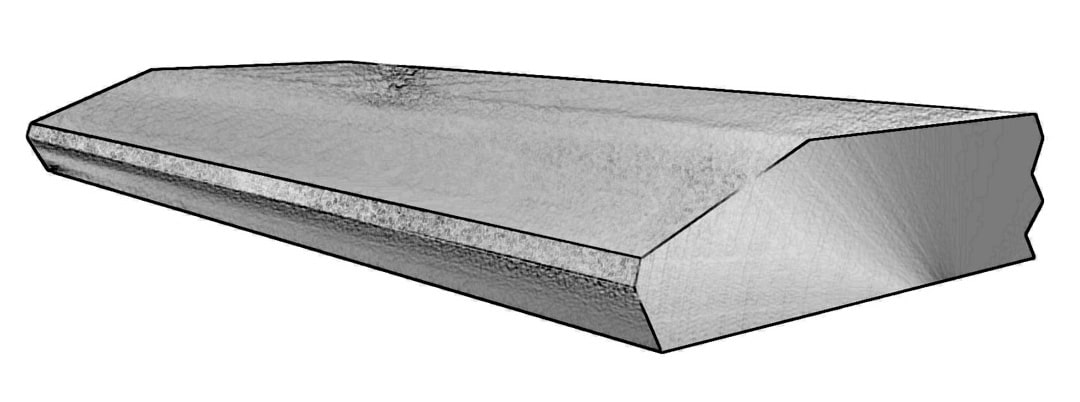

EXAMPLES OF POSSIBLE EGDE FORMS FOR PLATE EDGE MILLING MACHINES PFM LL

HIGHLIGHTS

Any Questions?

Please contact us!

FIELDS OF APPLICATIONS:

TANKS AND WINDTOWER COLUMNS

TRAPEZOIDAL AND CONICAL PLATES POSSIBLE

| WIDE-RANGING TYPE DIVERSITY |

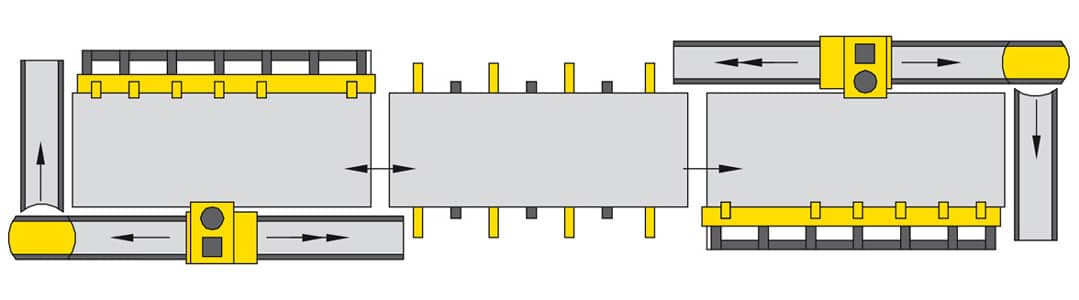

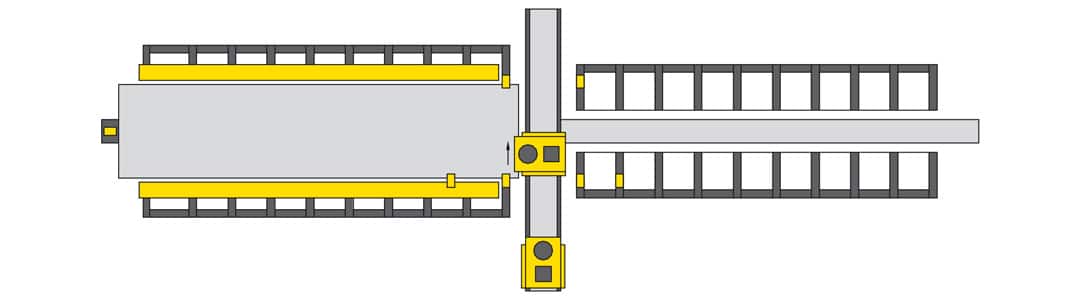

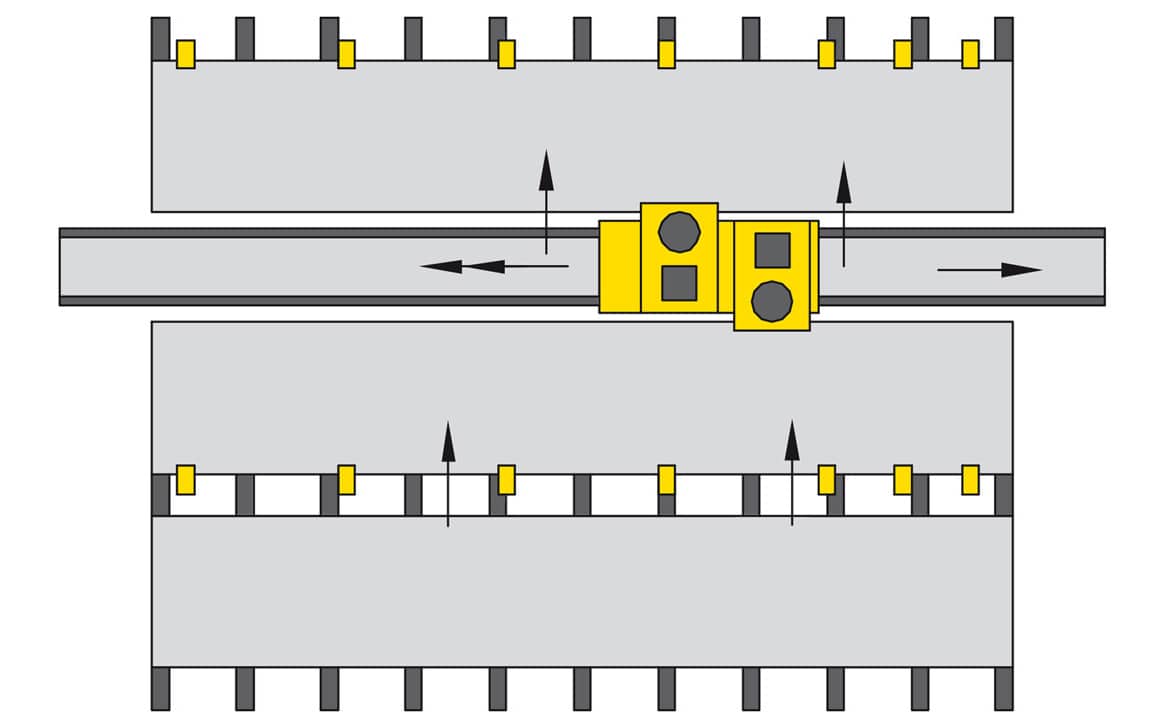

Typ PFM LqLq

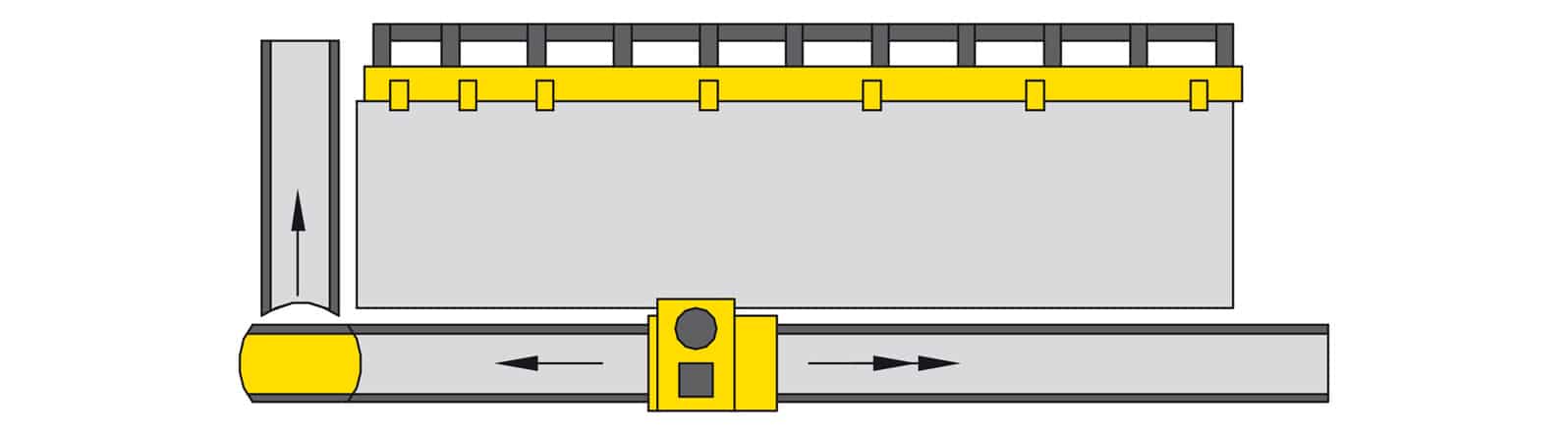

Typ PFM Lq

Typ PFM LLqq

Typ PFM L

HIGHLIGHTS

Any Questions?

Please contact us!

FOR SHIPYARDS

INCREASED QUALITY

THROUGH HIGH-PRECISION PLATE TOLERANCES

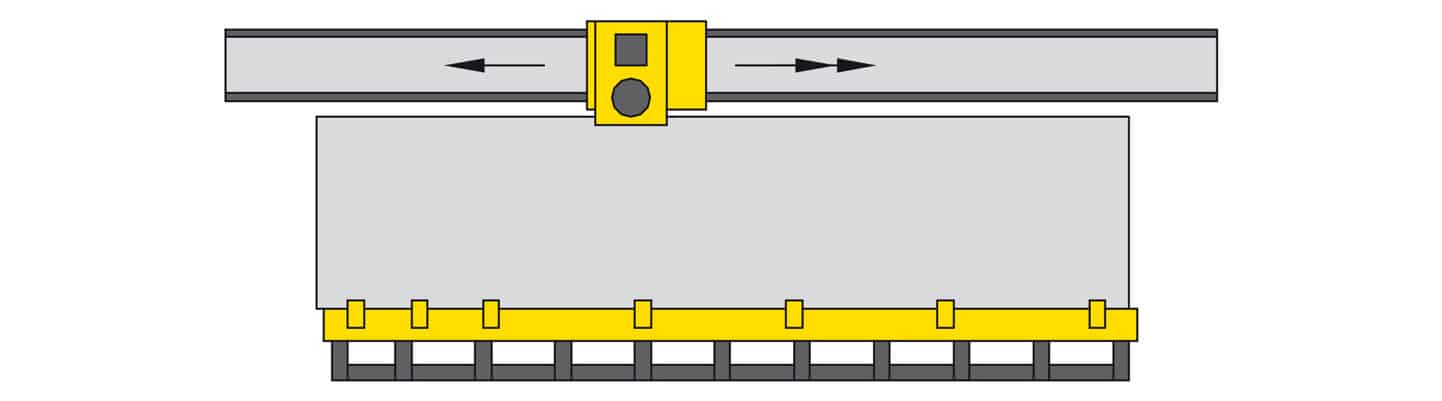

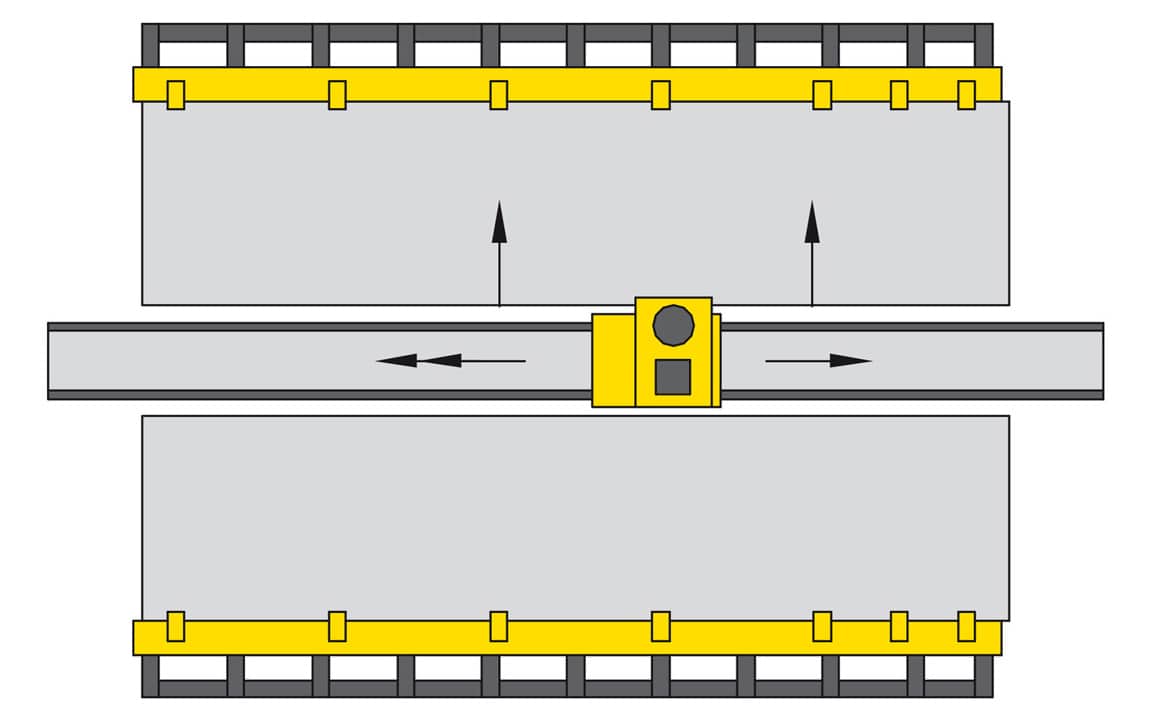

Typ PFM DT LQ

Typ PFM DT I

Typ PFM DT II

HIGHLIGHTS

Any Questions?

Please contact us!

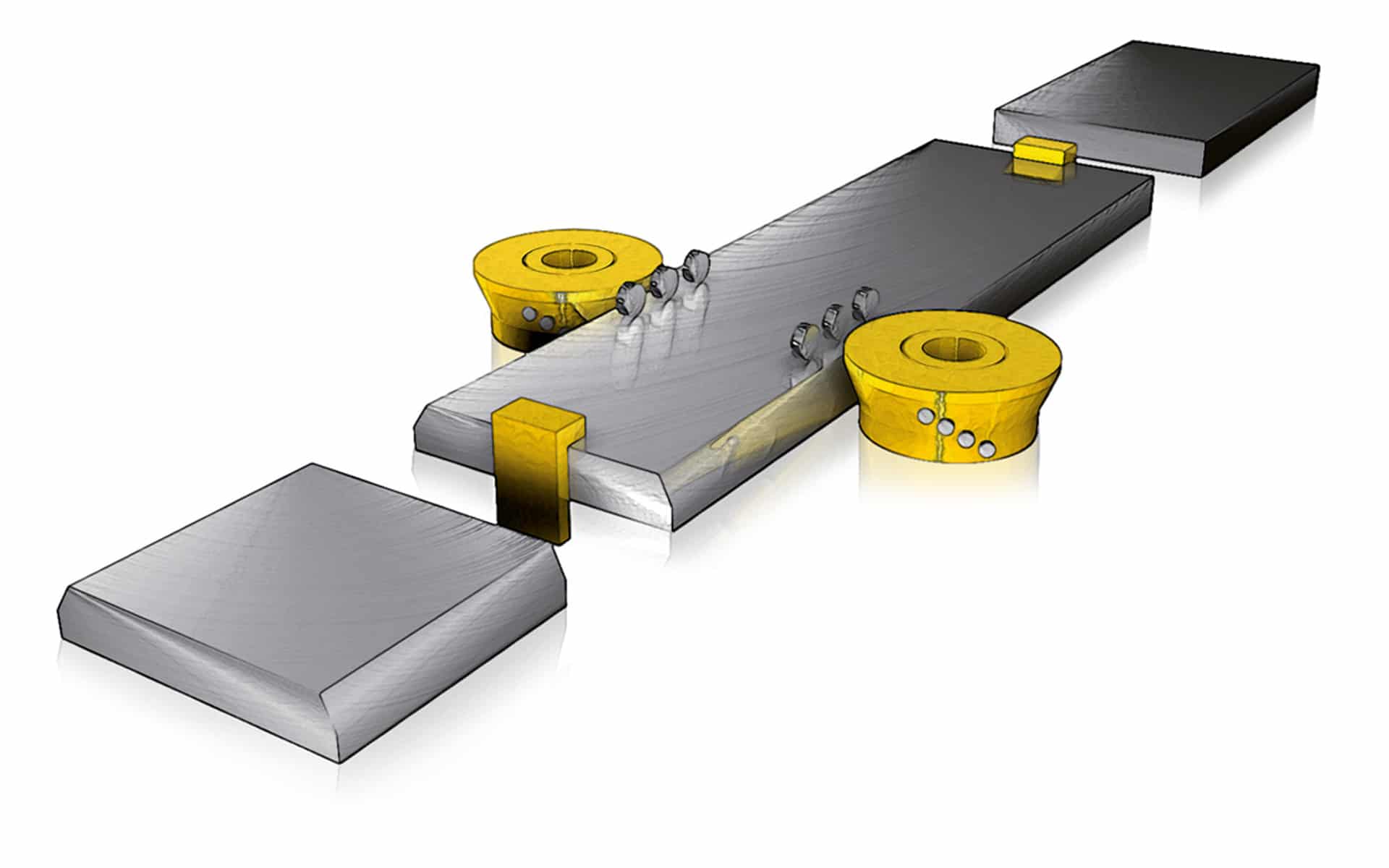

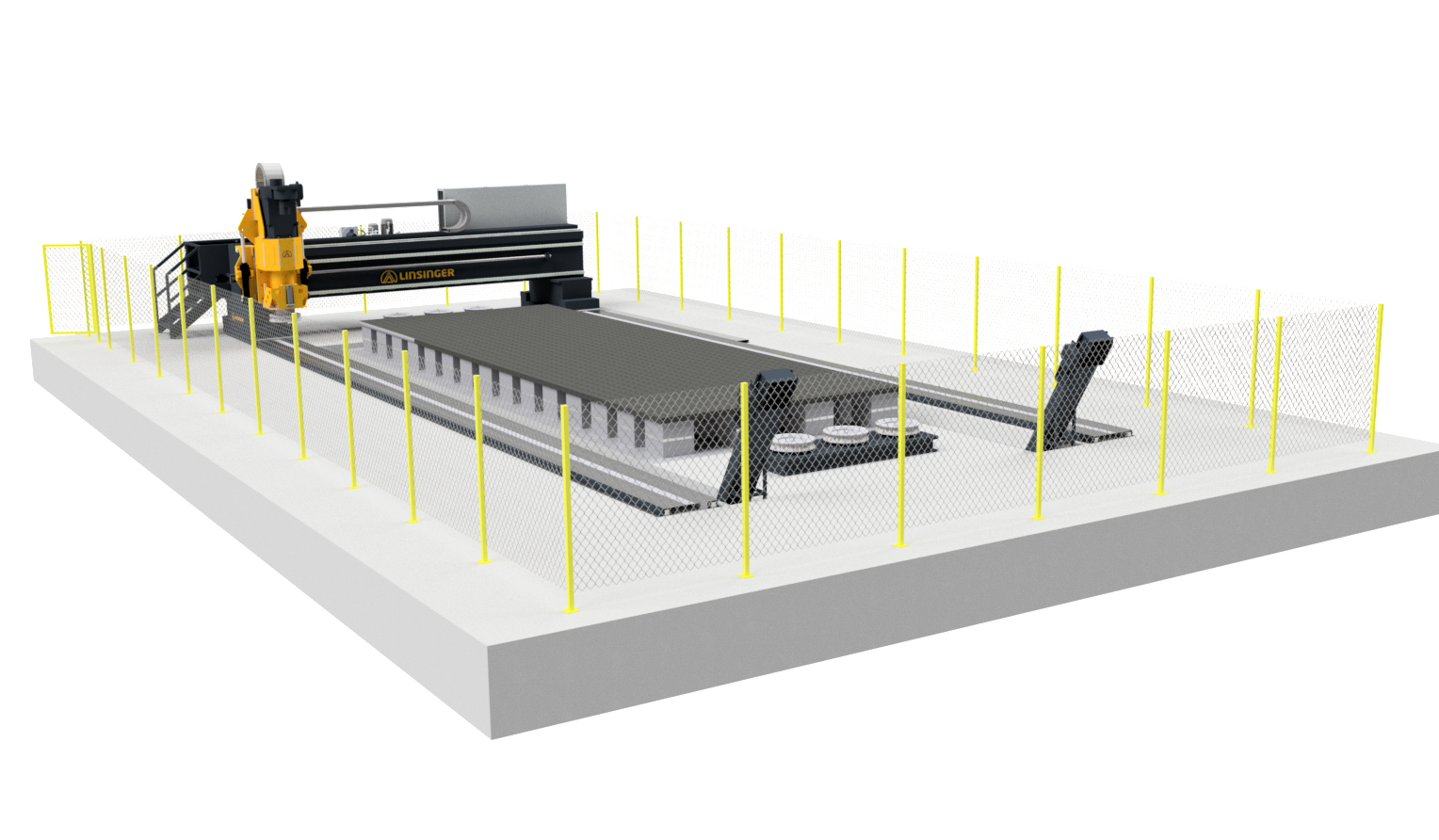

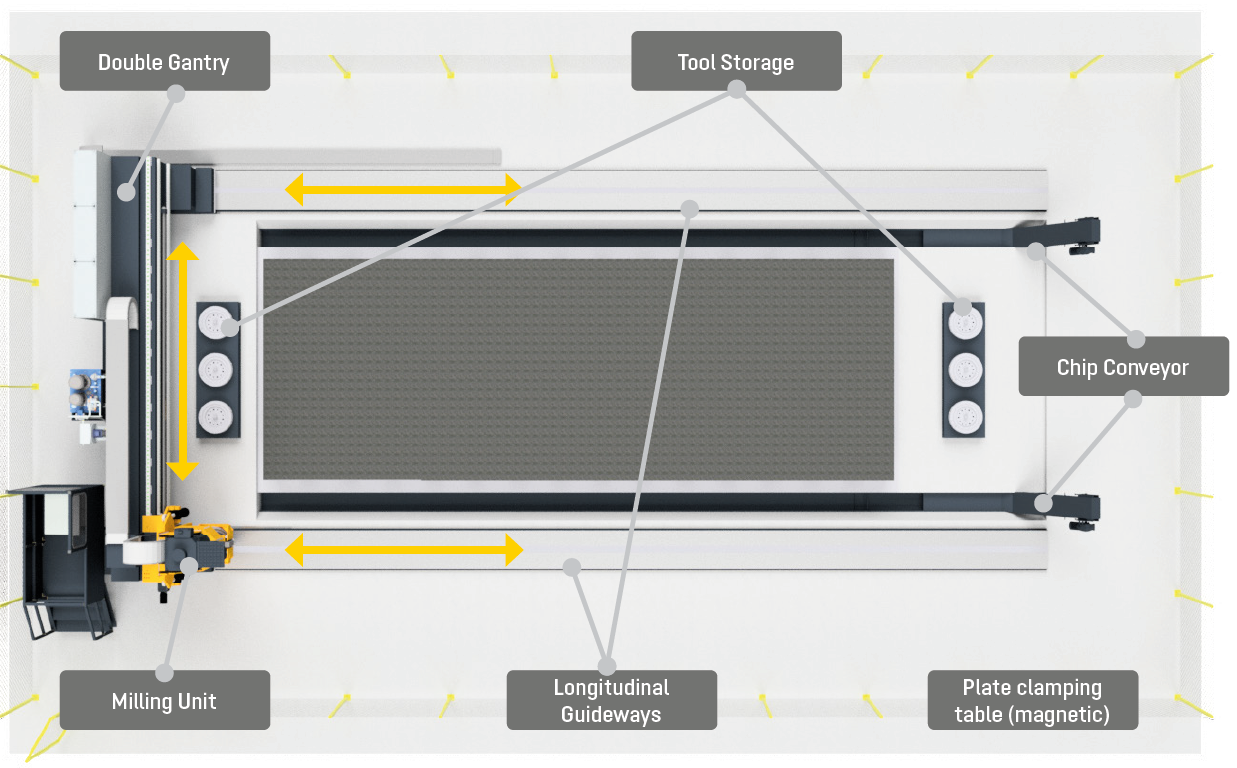

FALCON - 4-Side Plate Edge Milling Machine

Linsinger’s latest plate edge milling machine generation PFM PT enables edge preparation on all 4 sides (2 longitudinal + 2 cross sides) of a plate in one clamping. Our proven “Linsinger Thick Chip Milling Technology” ensures high feed and output rates at lowest possible tooling cost.

Due to the gantry milling concept and the magnetic clamping units, highest flexibility is given and even complex plate shapes such as trapezoidal and curved plates (e.g. for the vessel and wind tower industry) can be processed. For non-magnetic and complex materials such as Stainless Steel, High alloyed steels, Duplex and Super-Duplex grades, special clamping tables are available. Optional minimum quantity lubricant spray nozzles ensure economic machining even of these materials.

The machine covers plate dimensions of up to 12,000 x 4,200mm (39,5 x 13,75ft) with wall thicknesses from 10mm up to 200mm (0,4 – 8”) – larger plate dimensions upon request. The high-power reserves of the machine ensure maximum torque and high feed rates even when heavy plates are milled. Various profile types (N/V/X/Y/J) can be realized. The proven copying function of the milling unit ensures a constant web-flow along the plate edge, even on heavily bent plates of high thickness.

FEATURES

technical data

Cycle time

20 min

12,000 x 3,000 mm

(40ft x 10ft)

t = 50 mm (2″)

Carbon Steel

AVAILABLE OPTIONS